At STM lab we use an in-house developed sample receiver stage in the PREP chamber manipulator which allows for measuring temperature directly on the sample via a K-type thermocouple (requires a custom-built sampleplate). The receiver is back-compatible with standard ScientaOmicron flag-type sampleplates, however, the vertical distance between the baseplate and the direct current contact may differ from that in original ScientaOmicron UHV systems. It is strongly recommended to get in touch with the lab staff well before your experiment if you are planning to use DC sampleholders.

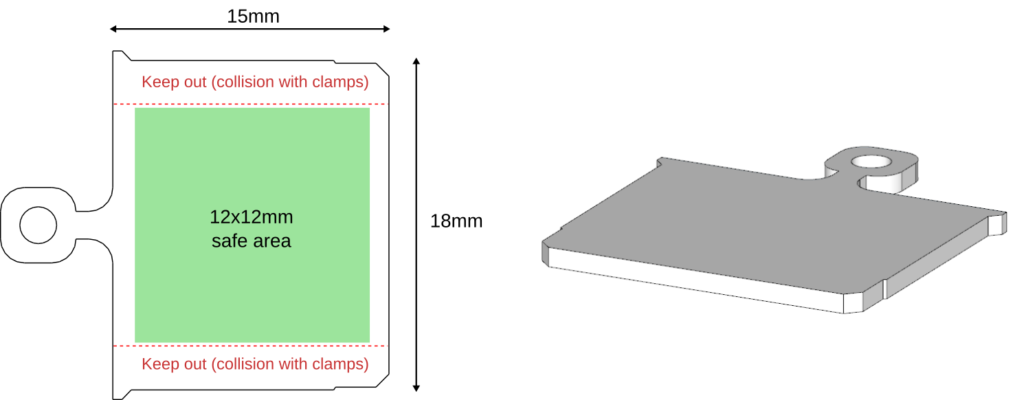

Standard (ScientaOmicron, Prevac, SPECS, etc) flat flag-type sampleplate. A number of these sampleplates (stainless steel or molybdenum for high temperatures) is available for users. The samples may be glued to the sampleplate using EpoTek HD21 conductive epoxy glue (cures at 150 oC, holds up to 450 oC); spot-welded using Ta foil; clamped with M 1.2 studs/nuts.

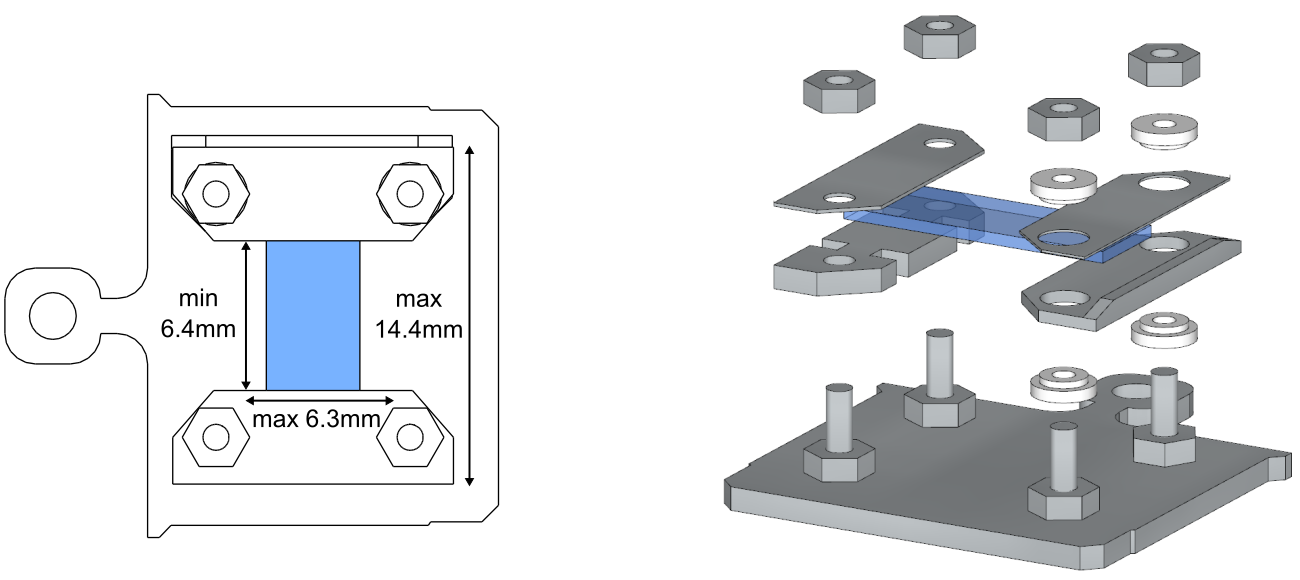

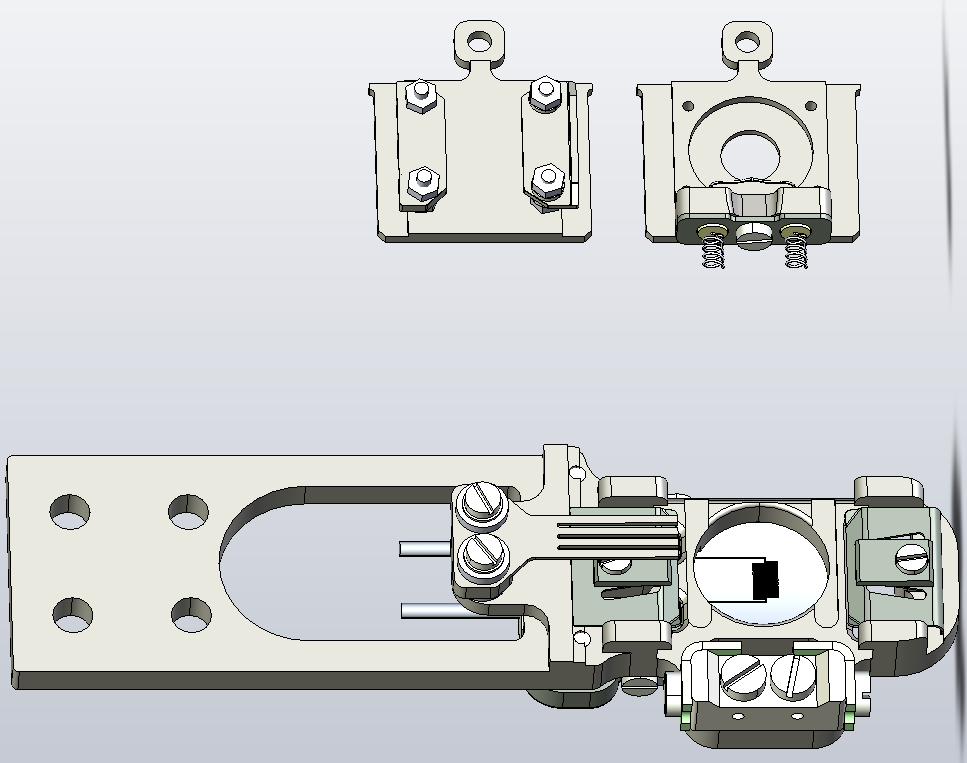

A “double-decker” sampleholder used primarily for annealing wafer-type samples (e.g. Si, Ge, etc). The DC power supply can provide up to 60 V of potential difference and up to 40 A current, however, maximum current is limited to 10 A (flash) and 6 A (prolonged annealing). Samples must only be mounted via clamping.

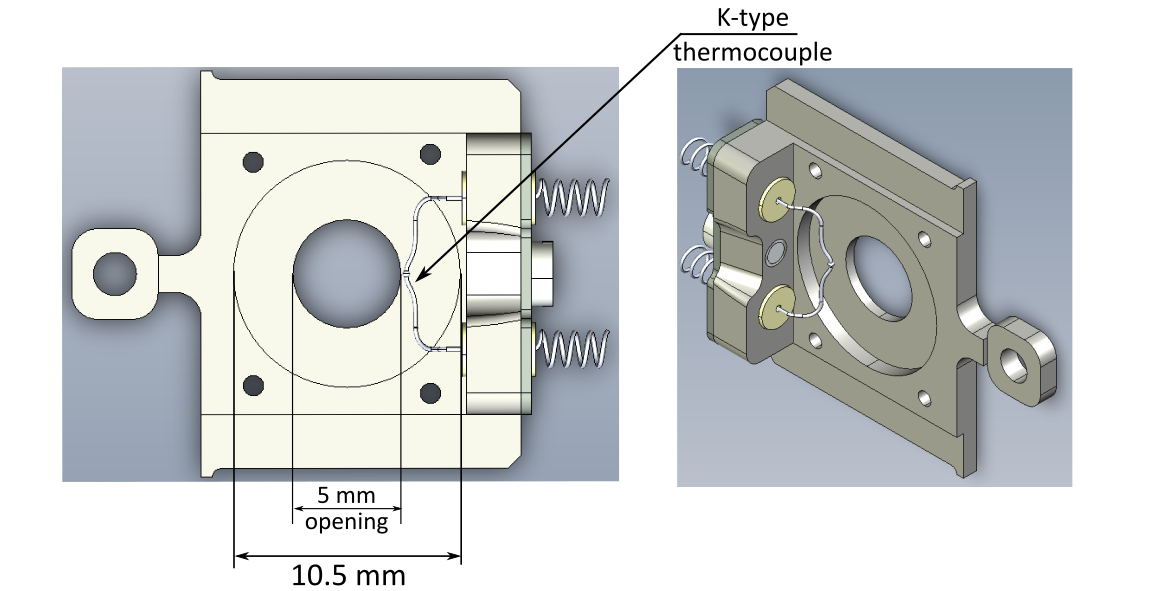

The sampleholder with temperature control capability. Mostly used for single crystals (preferably hat-shaped) that are held in place by a custom-made mask from Ta foil clamped to the SH using M 1.2 Mo studs and Ta nuts. Spot-welding with Ta foil is also possible, but not adviced. The hole in the middle is for improving the efficiency of e-beam heating, however, for sensitive samples and for reducing the temperature gradient a Ta foil may be spot-welded above. These sampleholders are only available upon timely request!

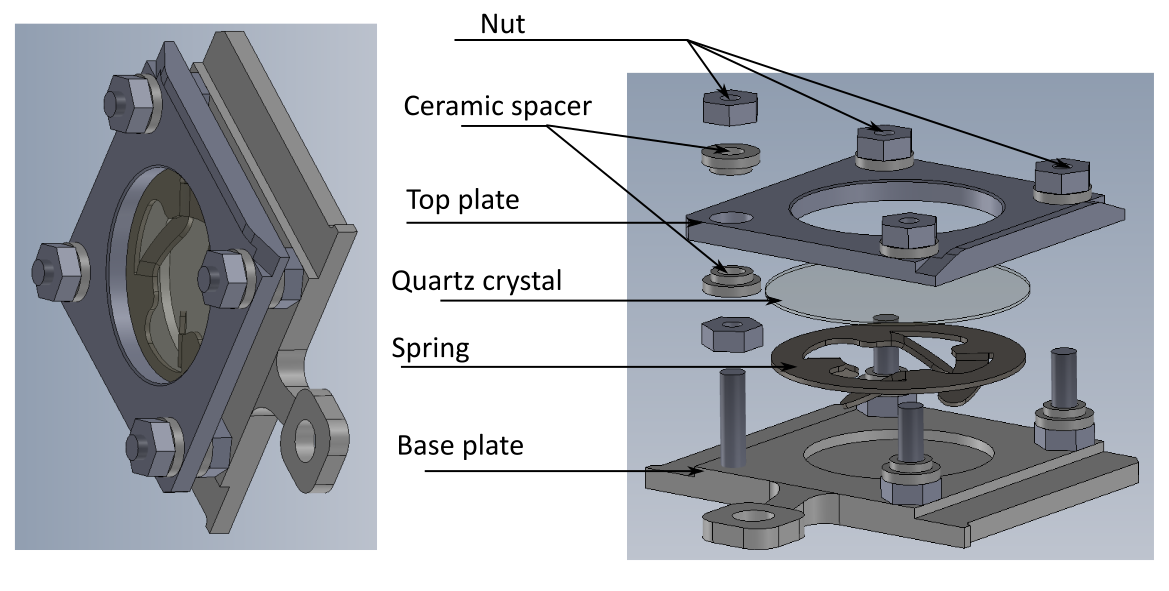

Movable quartz microbalance allows for measuring the deposition rate exactly at sample position, releaving the geometrical constraints for placement of molecular/atomic sources. The idea inspired by the following publication: “Movable holder for a quartz crystal microbalance for exact growth rates in pulsed laser deposition”