The large working distance at the NanoMAX endstation means that there is room for various sample environments. Below are listed standard beamline provided sample environments (electrical, nano-indenter). Additionally, examples of user provided sample environments that have been used previously are described below. If you intend to bring and use your own sample environment, contact the beamline staff to discuss feasibility before submitting a proposal. If you are in need to a specific sample environment, but don’t have one, also contact the beamline staff, as we can connect you to previous users that might have a suitable instrument.

Beamline Provided Sample Environments

A few beamline provided environments/setups are available to all users. These include electrical biasing, XBIC, and nano-indentation.

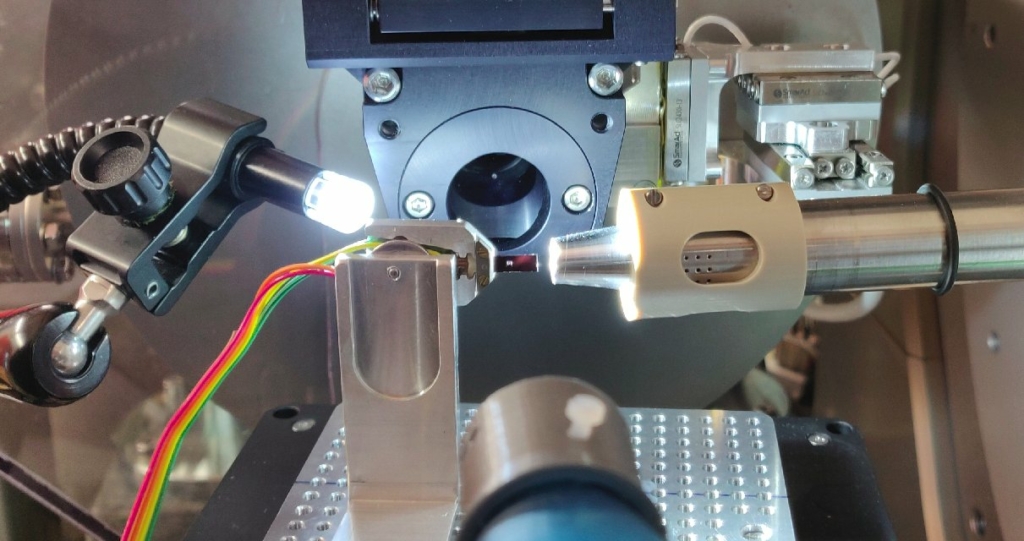

Electrical biasing / XBIC

A Keysight B2985A Electrometer is available for operando biasing of samples up to 1000 V. Additionally, X-ray beam induced current (XBIC) measurements are also possible using the Keysight ammeter. A Keithley 2470 may also be available upon request.

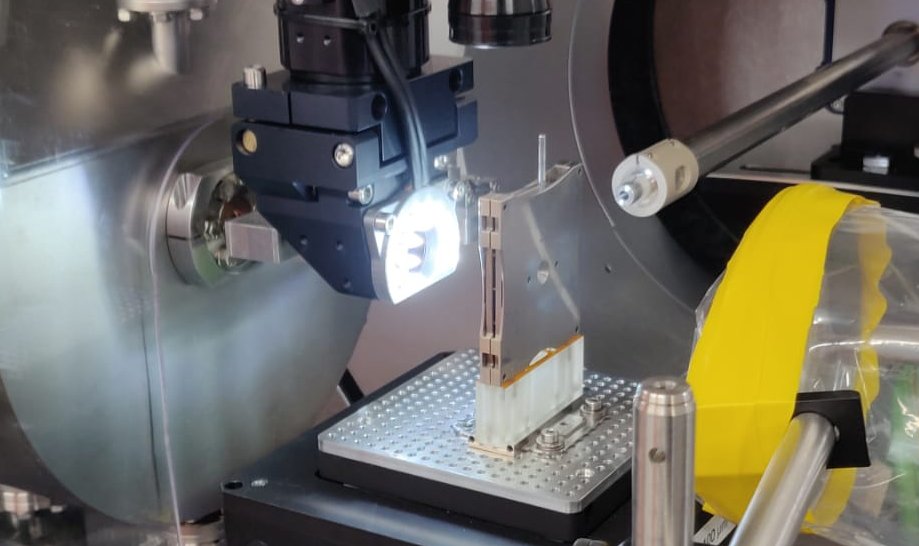

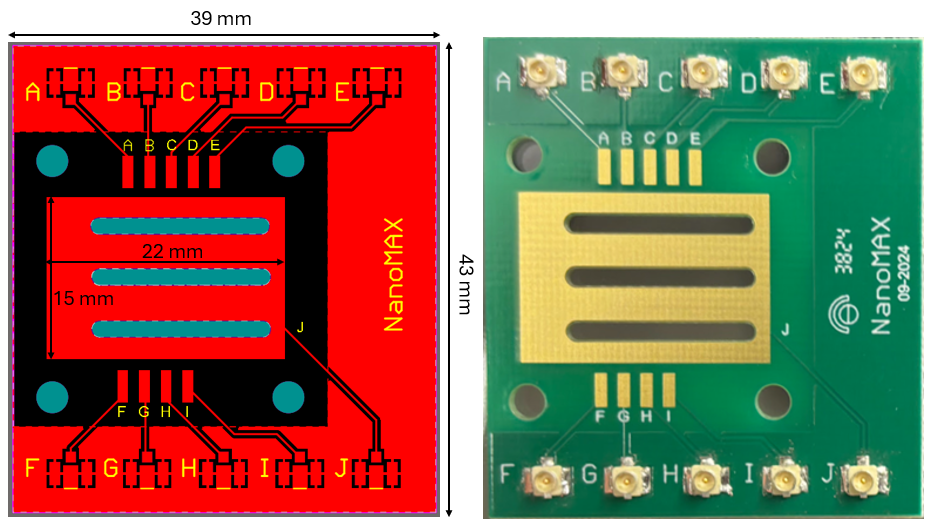

The beamline can provide users with printed circuit boards (PCBs) that are compatible with both transmission and reflection geometries at the Diffraction end station. Devices must be wired bonded to the PCBs at the users home institution, but additional wire bonding during the experiment may be possible at MAX IV. Please contact Megan Hill with any questions.

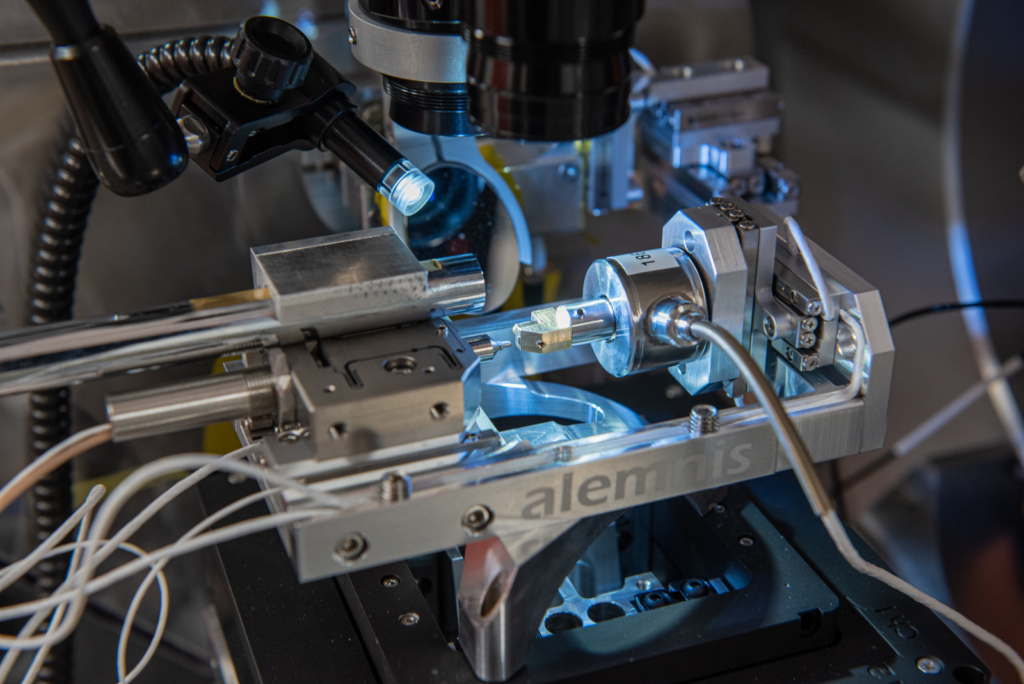

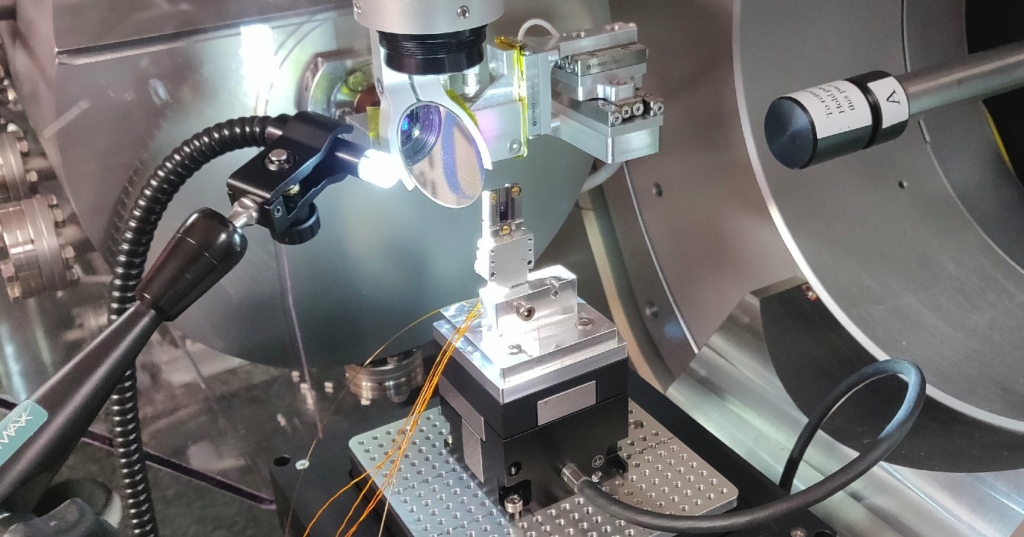

Nanoindenter

A nanoindenter which allows for in-situ nano-diffraction experiments while a push or pull force is acting on the sample is available at the beamline. Sample requirements for this system are strict. Please contact Sebastian Kalbfleisch with any questions or if you are interested in applying for beamtime using the nanoindenter.

User Provided Sample Environments

As mentioned above, light and compact sample environments may be accommodated if it they are provided by the user group and the feasibility has been checked by the beamline staff prior to proposal submission. The rough requirements for a sample environment to be considered are: maximum size roughly that of a tennis ball (smaller is better); maximum of 2 kg (much lighter is much better); safe to use; no thick stiff cables/hoses/tubes that would exert force on the piezo scanning stage. The details always differ from case to case. Make sure to discuss your requirements with the beamline staff.

The following are examples of environments previous users have implemented at the beamline. These environments are user provided and are unfortunately not available for general use. They are listed merely to demonstrate the possibilities at the beamline. Please contact beamline staff if you have any questions.

Sample heater allowed studying temperature-dependent phase transitions up to 350 °C

Light weight and compact cell allowed for coherent Bragg imaging under electrochemical conditions.

Holder allowed to mount diamond anvil cells (DACs) which facilitated measuring diffraction from sub-micron crystallites under extreme pressure.

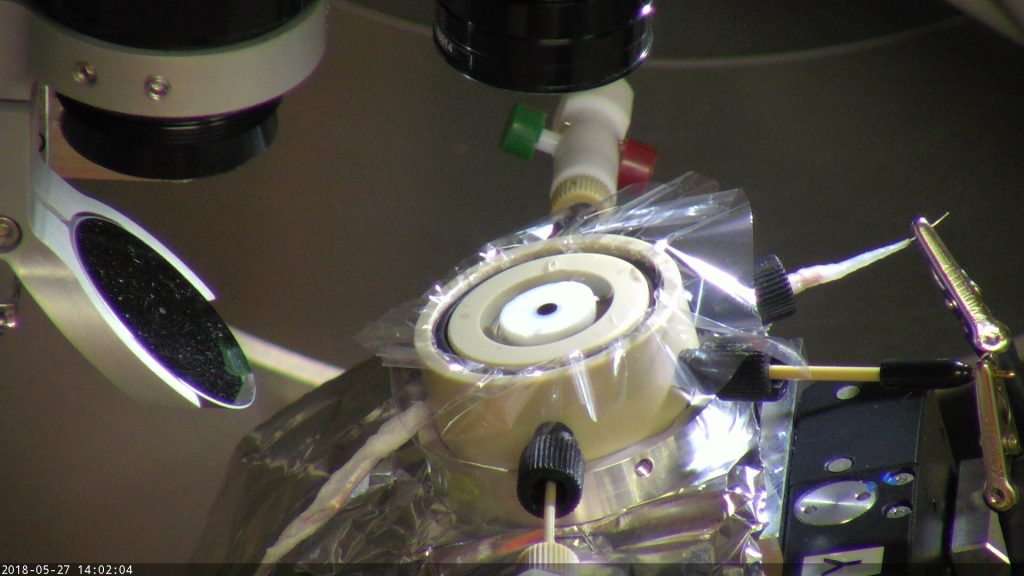

Nano-reactor based on commercial MEMS chips allowed for in-situ measurements in transmission geometry while the (small) sample could be heated and the atmosphere the sample was in could be controlled.

References: 1

Commercial MEMS chip design allowed for heating microscale samples in ambient atmosphere and allowed for measurements in transmission geometry with simultaneous XRF measurements.

device from DTU Energy and DTU Nanolab

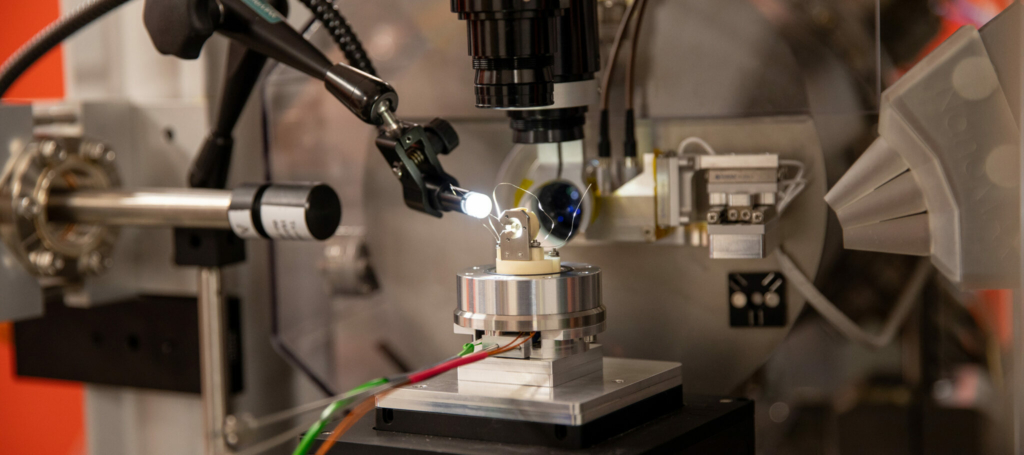

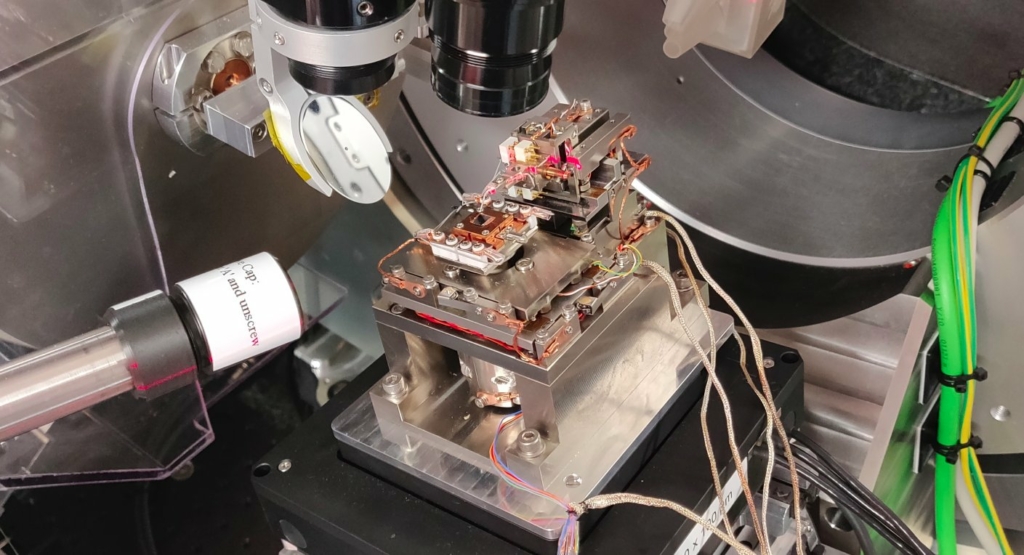

A small AFM / STM setup was mounted on top of the piezo scanner. It allowed for parallel X-ray measurements in reflection geometry.