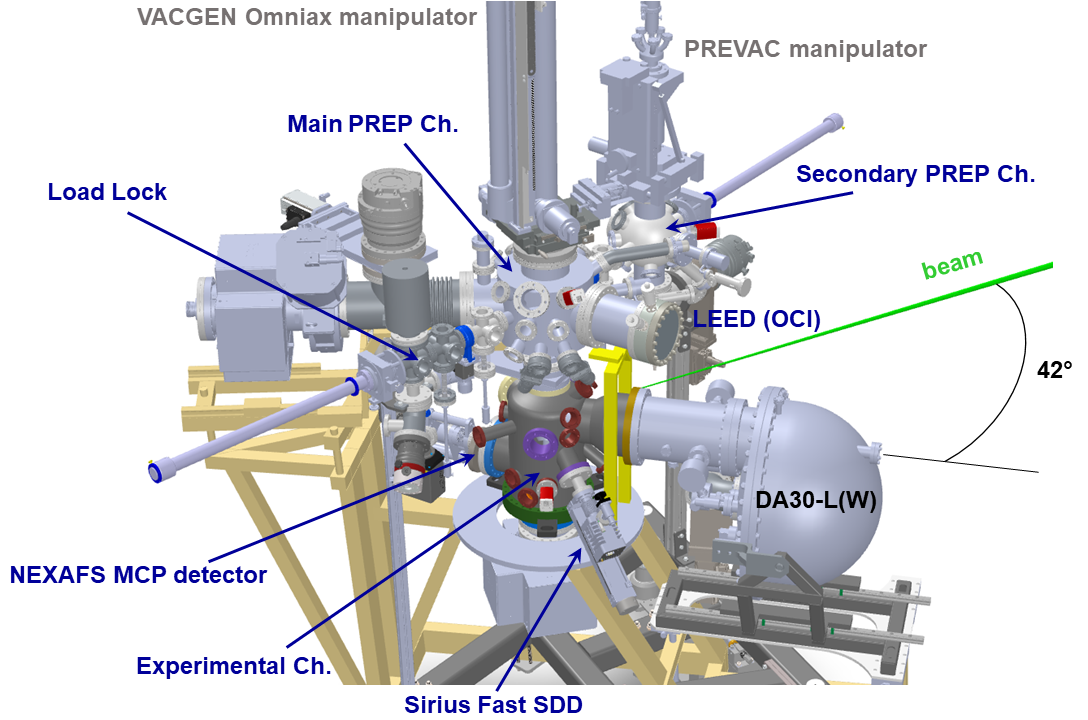

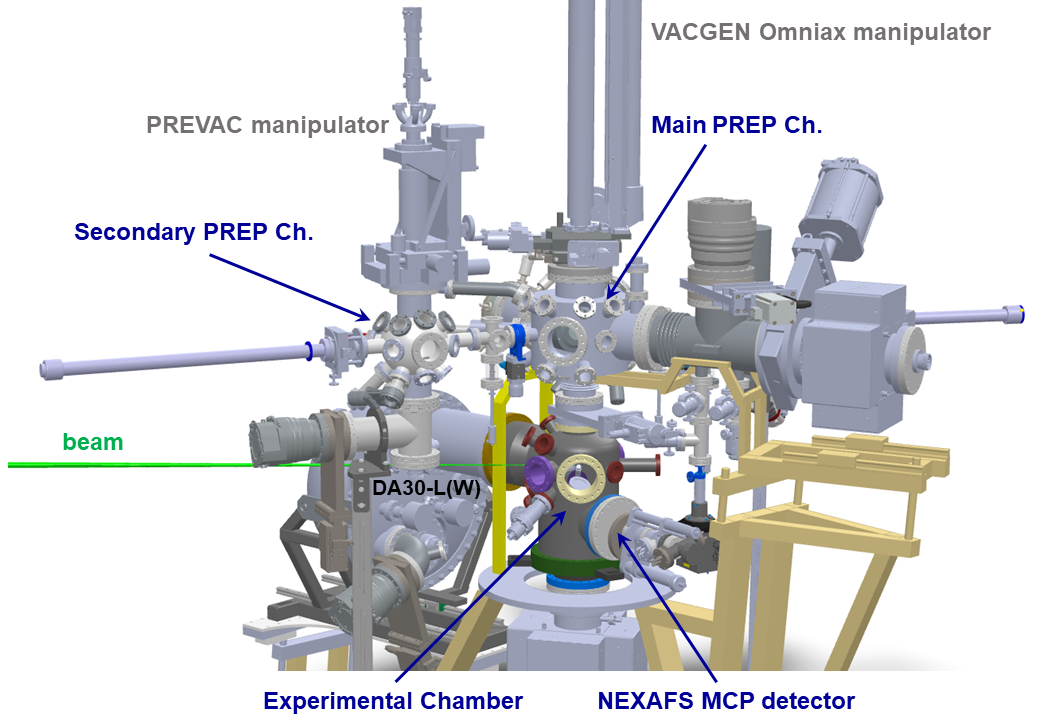

The permanent UHV end station EA01 on the SMS branch is dedicated to photoelectron and x-ray absorption spectroscopy studies on surfaces and thin films. It comprises four chambers: an analysis chamber with detectors, two preparation chambers with sample transfer and treatment facilities, and a fast entry chamber with a sample garage. The main characteristics of this system are detailed below.

A 3D model of this system is available to the potential users on request.

Analysis chamber

| Base pressure | 3⋅10-10mbar |

| Sample manipulation | 4-axis LHe/LN2 manipulator (VG Omniax): 3 motorized translations x,y = ±12.5 mm, z = 600 mm and 1 motorized rotation: 290° polar angle range Absolute encoders for precise positioning Omicron flag-type sample holders |

| Source | LPU 54.4 mm |

| Beam size at sample | Defocused (FWHM, h x v): up to 1 x 0.4 mm Focused (FWHM, h x v): 50 x 0.75*[exit_slit_opening] μm; further reduction in size is possible with baffles (at the cost of flux) (see picture) |

| Cooling | Open-cycle He-flow cryostat (a custom-made variant of Janis ST-400) LN2: ~90 K on sample (most standard mode of cooling) LHe: ~21 K on sample (Cu-manipulator head, requires venting, rebuilt and baking) LHe: ~35 K on sample (Mo-manipulator head) On-sample K-type thermocouple sensor for both heads (transferrable with the sample plate) to ensure exact T measurements If necessary, a Si-diode sensor may be mounted close to the sample area for more precise low-T measurements (at the cost of reduced heating capabilities) |

| Magnetic shielding | μ-metal liner |

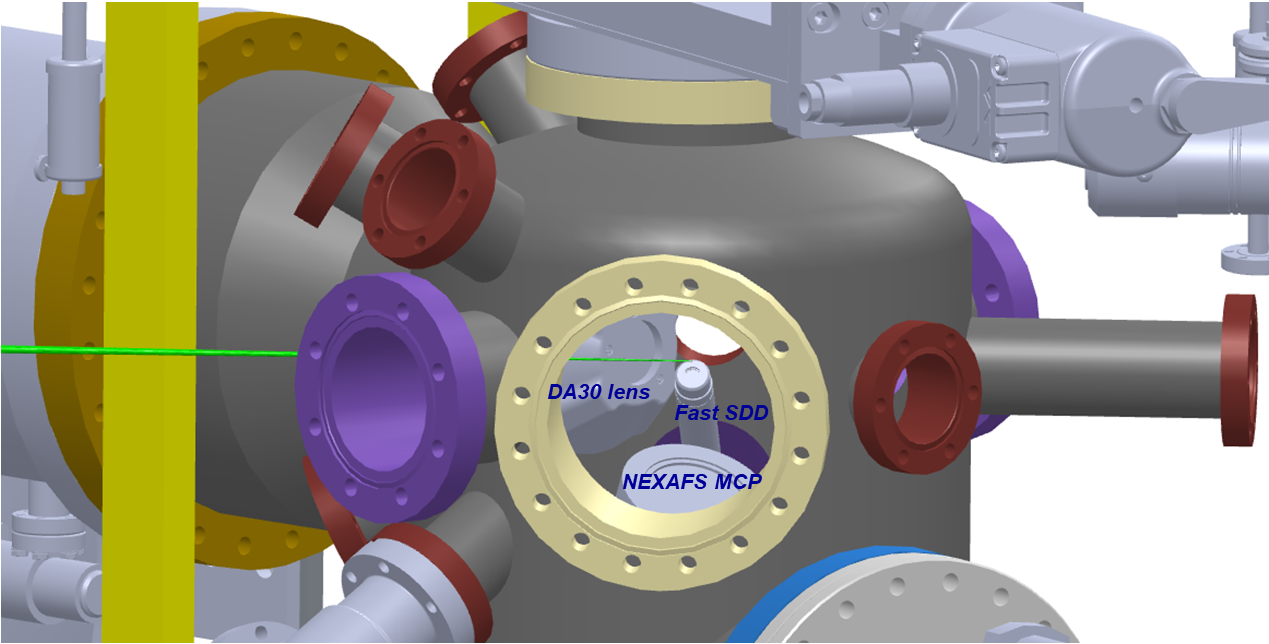

| Detectors | - DA30-L(W) analyzer since summer 2021 - NEXAFS MCP detector for PEY and TEY experiments - NEXAFS in TEY mode via sample drain current - NEXAFS in partial FY mode with Sirius 70 mm2 active area SDD (Rayspec) and Xspress3mini pulse processor (Quantum Detectors) |

Main preparation chamber (for relatively clean sample preparation procedures)

| Base pressure | 3⋅10-10mbar |

| Sample manipulation | Same main manipulator as for the analysis chamber (VG Omniax); magnetic transfer arms (Ferrovac) |

| Sputter gun | Yes (IS 40C1 from Prevac) |

| Heating | Two types of manipulator heads are available depending on the temperature range of an experiment: 1. Mo-based manipulator head for better heating. Radiative heating by filament (up to 800 °C), e-beam heating (up to 1200 °C, but only very shortly) and direct current heating (up to 1400 °C) 2. Cu-based manipulator head for better cooling. Up to 200 °C with a button-heater. On-sample K-type thermocouple sensor for both heads. |

| Cooling | Same as for the analysis chamber |

| Characterization | LEED (OCI Vacuum Microengineering, LPS075-D) RGA (MKS Microvision 2) |

| Deposition | 2 quick install deposition source ports CF 40 (behind a gate valve) with pumping Quartz thickness monitor (from Prevac) Additional CF40 ports if necessary Evaporators on request |

| Dosing | Gas-sending system with 4 separate gas lines (more on request) and 1 liquid vapor line connected to leak valves on the chamber; gas cabinets and pumping (please discuss gas usage with BL staff in advance) |

| Sample storage | Sample garage for storing up to 6 samples in UHV |

| Other | On demand: wobble sticks, vacuum files, vacuum cleavers, vacuum screwdrivers, etc. Possibility to attach vacuum suitcase for transfer samples to/from MAX IV STM (to be requested in advance). |

Secondary preparation chamber (for molecular film depositions and other less clean preparations)

| Base pressure | 5⋅10-10mbar |

| Sample manipulation | 4-axis LN2 manipulator (Prevac, customized): 3 translations: x,y = ±12.5 mm, z = 150 mm 1 rotation: -180°…+150° polar rotation Only z and rotation are motorized Magnetic transfer arms (Ferrovac) |

| Sample storage | Sample garage with slots for 6 plates |

| Sputter gun | Yes (IS 40C1 from Prevac) |

| Heating | Mo-based manipulator head, on-sample K-type thermocouple sensor Radiative heating by filament (up to 800 °C) Electron beam heating (up to 1200 °C) Direct current heating (up to 1400 °C) |

| Cooling | Heat exchanger with compressed air cooling (to avoid overheating); can be used with LN2 if necessary (minimum T ~ 160 K) |

| Deposition | 4 CF40 ports for user supplied evaporation sources, 2 of them gated with valves for quick equipment installation Thickness monitor on request |

| Dosing | Two gas lines + leak valves (one of them always for Ar) |

Fast entry chamber

| Ultimate base pressure | Down to 3⋅10-8mbar |

| Sample storage | Capacity: 6 sample plates |

| Venting time | 30 sec |

| Pumping time | 20 min to enable transfer (p = 2⋅10-6mbar); 2 hours + LN2 trap to reach ultimate base pressure |

Analyzer

| Type | Scienta DA30-L(W) (a version of DA30-L with extended Ekin range in deflection and angular modes) |

| Acceptance | 30° full cone acceptance without sample rotation (±19° in Transmission mode) |

| Energy resolution | < 1.8 meV FWHM at 2 eV pass energy and 20 eV kinetic energy |

| Angular resolution | < 0.1 degree in both Theta X and Theta Y |

| Detector | 40 mm MCP/CCD detection system: - Energy channels available simultaneously: >1000 - Angular channels available simultaneously: >750 - Total noise counts for all energy channels: < 2 cps - Average noise per channel: < 0.01 cps - Available dynamic range per pixel: > 7 bit - Detector information read-out rate: 400 Mbit/s |

| Slits | Orientation: horizontal Shape: straight for all sizes Width in mm (without aperture): 0.1 , 0.2, 0.3. Width in mm (with aperture): 0.2, 0.3, 0.5, 0.8, 1.5, 2.5. |

| Modes | Transmission (up to 1500 eV) Transmission XPS (up to 1500 eV) Deflector-Angular ±15° for 0.1 and 0.8 mm focus (up to 200 eV) Angular ±7°,±15° , for 0.1 and 0.8 mm focus each (up to 200 eV) |

| Pass energies | In Angular and Deflection modes: 2, 5, 10, 20 and 50 eV In Transmission mode: 2, 5, 10, 20, 50 100 and 200 eV |