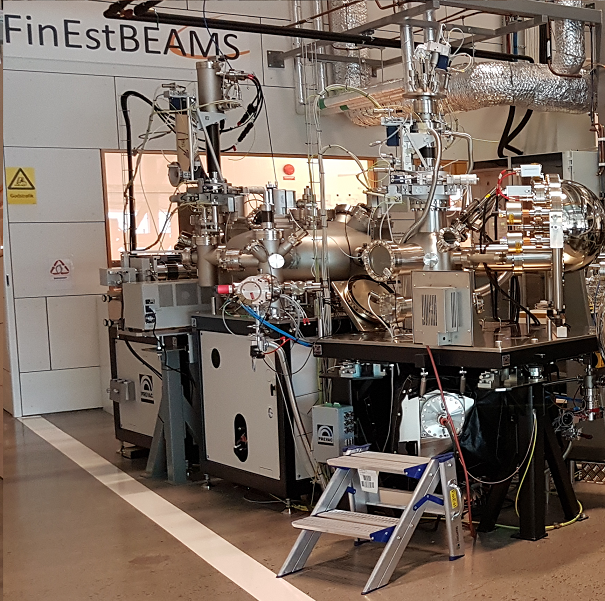

The solid-state end station (SSES) is designed for studying solid-state material via advanced experimental techniques in an ultra-high vacuum (UHV) environment. The end station is composed of four UHV chambers connected by a radial distribution chamber (RDC), i.e., analysis chamber (ANA), preparation chamber (PREP), storage chamber (STO) and load-lock chamber (LL). The design of the system allows sample transfer from a vacuum suitcase to the PREP. All the chambers can be pumped and vented independently. The base pressure of the LL is 1×10-9 mbar or better. A maximum of 12 samples can be loaded at the same time. A quick sample transfer from the LL to the RDC is allowed in a pressure of ~5×10-8 mbar, approximately after eight hours of pumping from air pressure. The STO can store 12 samples at the base pressure of 5×10-10 mbar.

The ANA is currently capable of photoelectron spectroscopy (PES) and X-ray absorption spectroscopy (XAS) measurements. The base pressure of the the ANA is 1×10-10 mbar. The main instrument is a hemispherical electron energy analyzer (PHOIBOS 150 2D-DLD from Specs). The manipulator in the ANA has 5-axis motorized motion, i.e., three linear motions and two rotational motions (polar and azimuth). A cryostat is equipped in the manipulator with the possibility of cooling the sample using liquid He and N2 through a transfer line. Resistive heating is available on the manipulator allowing measuring samples in various temperatures. The ANA chamber is equipped with a quadrupole mass spectrometer (QMS).

The base pressure of the PREP is 1×10-10 mbar. The manipulator has four-axis motorized motions, i.e., three linear motions and one rotational motion (polar), and two sample stations with possibilities of direct heating, resistive heating, electron beam bombardment and liquid N2 cooling. The PREP is equipped with a LEED/AES (low energy electron diffraction/Auger-electron spectroscopy) and a QMS. There are possibilities for quick loading of an evaporation source, evaporation cell, etc., in the PREP without venting the main chamber. A pumping manifold for users with special requirements, an ion gun for Ar+ sputtering, and a separate gas line with a leak valve are available.