As a world-class research infrastructure, MAX IV Laboratory, in collaboration with our users, funders, and stakeholders, aims to lead in addressing the United Nations Sustainable Development Goals (UN SDGs). The MAX IV organisation shares the same vision and goals for sustainability as our host, Lund University.

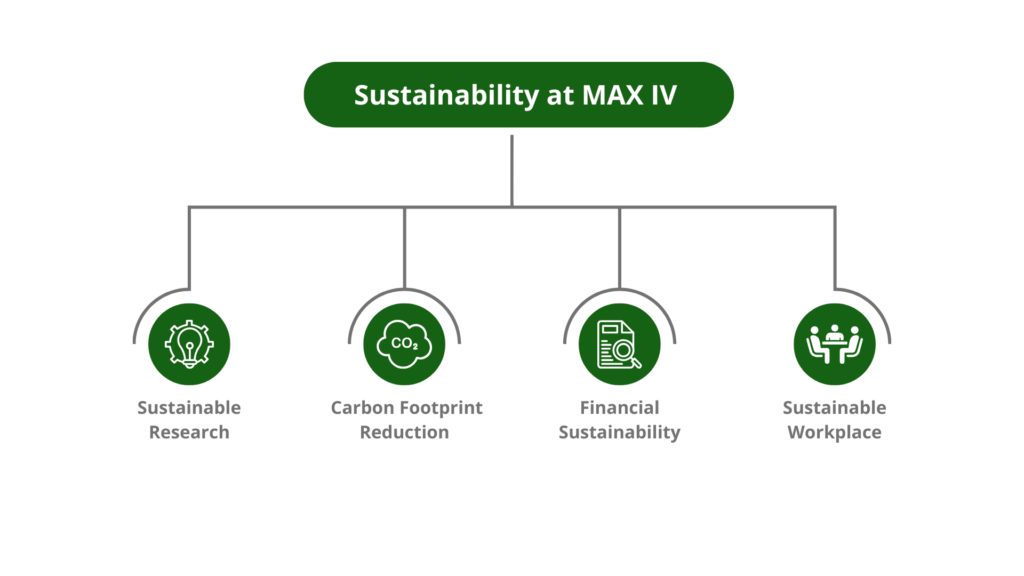

The overall sustainability work at MAX IV is documented in our Action plan for sustainability, which can be categorised into four priority areas:

MAX IV provides cutting-edge X-ray experimental techniques to support the needs of our academic and industrial user communities for sustainability research. This commitment to sustainability is a foundational aspect of the MAX IV Strategic Plan for 2023-2032.

Some recent examples of developments at MAX IV include a dedicated electrochemistry station at HIPPIE beamline targeting battery research, and the new FORMAX beamline beamline, which enables collaboration between academia and the forest industry to target new materials from Swedish forests.

To secure future needs in specialised trained staff with deep knowledge and understanding of offered methodologies, MAX IV supports and promotes education of next-generation synchrotron researchers and accelerator developers. One example is the EU-cofunded programme Prismas. Additionally, MAX IV collaborates on many EU funded calls focused on sustainability, such as ReMADE@ARI and RIANA.

All the energy utilised at MAX IV comes from sustainable and renewable sources. It is also a very energy efficient facility due to the technical design of the accelerator and the buildings. The different new techniques developed for MAX IV reduce energy consumption compared to traditional synchrotron facilities. The smaller magnets, the lower frequency used in the RF cavities and the NEG coating in the storage rings make the MAX IV less energy-consuming than any other synchrotron.

Great efforts have been made to recycle and reuse the excess heat generated from the linac and accelerators. All accelerator equipment is connected to a cooling system with heat exchangers and heat pumps which makes it possible to reuse the excess heat via the district heating system in Lund, in exchange for cooling water for the accelerator equipment. This is not only a way to make excellent use of all the excess generated heat but also reduce facility operational costs and reduce the carbon footprint.

The design and construction of MAX IV are based on the latest techniques and expertise, and the facility has been classified as a “Green Building”, “Miljöbyggnad Guld” and “BREEAM Outstanding”, among others, in accordance with the new Swedish environmental guidelines. MAX IV was the first building to receive the classification of BREEAM-SE. To attain the high environmental standard Miljöbyggnad Guld, an extensive programme for sustainable construction was implemented. This involved the installation of led lights in all buildings, controlled ventilation, and green roofs that help stabilise temperature in the experiment halls, while storing and delaying rainwater drainage, reducing the impact on the sewage systems and improving the wildlife environment. The construction process included goals for sustainability, for example, “greener” logistics, low energy consumption, minimum waste, and waste management. Read more via Smart City Sweden.

The MAX IV landscape complies with the high sustainability agenda for the area. For example, all the cut and fill from the excavations were kept on site and are reshaped into a hilly landscape, constructed to reduce vibrations and to maximise the land surface area. This provides spaces for more grass, flowers, recreational areas, birds and amphibians. To further enhance the ecological diversity, a mix of seeds from the nearby nature reserve Kungsmarken and from local businesses is sown on the slopes. Water is an important feature for wildlife and also enhances the biological diversity, so rainwater ponds including wetland vegetation have been introduced.

Reducing MAX IV’s carbon footprint is a continuing mission. The EU-funded project Research Infrastructure (RF 2.0) initiated in 2024 with coordination by the Karslruhe Institute of Technology (KIT) and participation by several European facilities, including MAX IV. The project focuses on improving energy efficiency and sustainability in large accelerator-based research infrastructures. MAX IV will contribute with the design of a permanent magnet-based alternative to the MAX IV 3 GeV ring dipole magnets. In addition, MAX IV will be involved with life-cycle assessment of the carbon footprint for permanent magnet and high efficiency radio frequency amplifiers.

In terms of financial sustainability, the MAX IV emphasis extends both to long-term financial planning and the incorporation of sustainability criteria throughout the procurement process.

The Public Procurement Act in Sweden states that sustainability requirements should be used in all procurements. This implies that MAX IV has the responsibility to impose criteria on procurement processes, requiring contributions to sustainability from the entities being procured. Sustainable procurement can lead to spending decreases for MAX IV as well as society at large if a life cycle cost is implemented. The MAX IV organisation currently has strategies for circular procurement such as requirements for warranties, spare parts, and service.

To establish the laboratory as a sustainable workplace, considerations for sustainability are applied on the individual, interpersonal, and organisational level This includes aspects of the working environment, company culture, and employee on and off boarding. Each area is being updated and improved to reflect this commitment.