One of the key challenges in catalysis research is to understand how catalysts’ structure and function relate to each other. Regardless of the type of catalyst in question, structure and function are dynamic with a strong dependence on the localized reaction conditions such as temperature, pressure, and gas composition just above the catalyst surface. Now, researchers developed a new event-averaging-based method employing time-resolved ambient pressure photoelectron spectroscopy to map catalyst structure and local gas environment simultaneously while reaction conditions change rapidly.

With this new method, scientists can determine in detail what triggers structural changes on the sample surface and even measure the activity during a structural transition. This enables scientists to examine active surface structures with ambient pressure photoelectron spectroscopy that only exists for sub-second time-scale during rapid transitional stages while running a chemical reaction.

In-situ catalysis studies are essential for understanding how catalyst structure and composition impact its activity. Ambient-pressure x-ray photoelectron spectroscopy (APXPS) is a powerful in-situ technique that accounts for all of these intertwined factors. Until recently however, APXPS’ relatively slow-paced spectrum recording capacities have limited its effectiveness as a tool to examine the dynamic changes of catalyst structure and composition that occur at sub-second time scales in response to changes in experimental process parameters such as gas composition, temperature, or pressure.

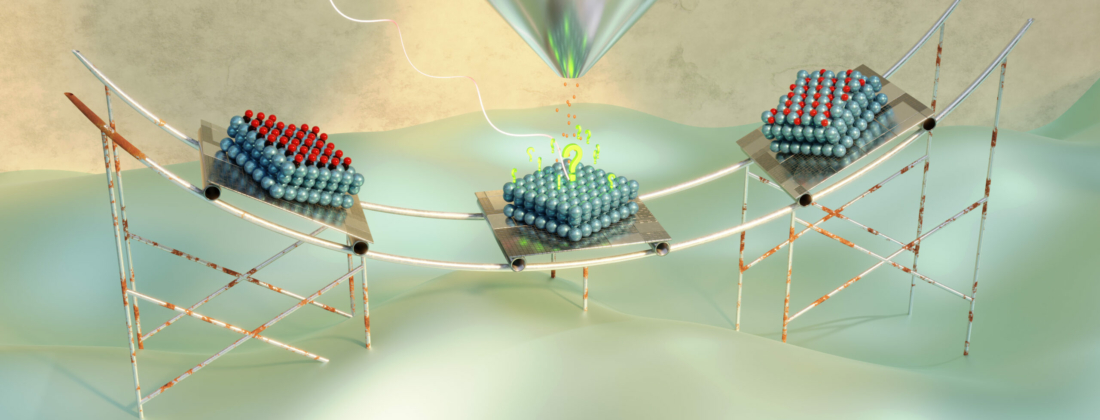

Recently, an international group of researchers from Lund University, Stockholm University, the Norwegian University of Science and Technology, DESY, and MAX IV developed a new method for observing catalyst restructuring at real sub-second timescales. The method is based on cyclic gas pulsing combined with APXPS and software-based event-averaging by image recognition of spectral features. This approach finally enabled scientists to obtain accurate and detailed insights about the dynamic processes occurring on catalyst surfaces as well as their origins.

MAX IV’s HIPPIE beamline provided the APXPS capacities crucial to the study’s success thanks in part to the beamline’s intense synchrotron x-ray light ideally suited for transient studies, according to Jan Knudsen, the study’s corresponding author, and MAX IV and Lund University scientist. Above all however, Knudsen singled out the beamline’s capacity for rapid gas exchange in the sample cell which allowed the scientists to use gas pulsing to circumvent APXPS’ relatively slow-paced spectrum recording.

“The surface transitions – that is how fast the catalyst surface restructures in response to the changing gas composition in front of the sample – happens at really short timescales, sub-seconds timescales,” explained Knudsen. “So, to follow this with APXPS that has an acquisition time of maybe 10 seconds or more, we need do what normally is called ‘pump-probe’ or more specific in our case ’pulse-probe.’ We simply change the gas composition rapidly and then we use this to drive the surface to a new surface structure. That is, we ’fire’ a gas composition pulse and this results in structural changes on the catalyst surface.” At this point the crucial event-averaging element of this new method came into play.

Firing many similar gas composition pulses enabled the researchers to average over many structural transition events with the same time resolution as used by the detector. A simple way to describe this is that we “start the watch when a gas pulse is fired, wait a certain amount of time, measure for a short interval, and repeat many times,” as Knudsen put it before pointing out a potential problem with this measurement strategy. If the gas pulses fail to be 100 % identical or if the catalyst does not respond in exactly the same way for each gas pulse, false conclusions will be the consequence of the event-averaging. What’s more, it is quite difficult then to realize that this is even happening.

To avoid such methodical shortcomings, Knudsen and his team instead took advantage of the fact that XPS allows for measurements of the localized gas composition near the catalyst surface. Rather than timing each transition-event relative to the time of firing a gas pulse, the scientists used software-based image recognition to capture spectral changes signaling a structural surface transition and hereby determined the absolute time of each structural transition event. Finally, the scientists could event-average over true surface transitions and construct event-averaged and time-resolved movies or image plots showing structural catalyst transitions and gas composition changes simultaneously with 150 ms time-resolution.

Event-averaging over many oscillations and high time-resolution also make it much easier to distinguish active catalyst surface structures from spectator structures present on the catalyst surface, the latter of which does not contribute to its activity at all. Differentiating these kinds of structures has previously often posed a significant challenge to static studies. “With event-averaged and time-resoled studies I might see that the coverage of a molecule or phase is growing while at the same time the catalyst activity is increasing. Then, I can say there is a correlation between the two observations and conclude that structural change of the catalyst is most likely the reason for the increased activity. You can also use the methodology for different techniques or use different perturbations such as pressure and temperature pulses,” Knudsen said.

“By event averaging we can improve the signal-to-noise ratio dramatically…Our method does not increase the time resolution, but by repeating over the course of many events, we can generate a movie that shows in slow motion how the catalyst changes structure or how molecules absorb how the catalyst surface becomes oxidized. At the same time, we can follow how the gas phases change. That’s really at the heart of what we want to do in catalysis research: Correlate what happens on the catalyst surface and what happens in the gas phase just above it.”